Project Aberration – 1956 SRT-10 Dodge Pickup Build

Aberration – Viper/Pickup Custom Build

Witness the Combination of a 1956 Dodge Pickup with a Dodge Viper SRT

Follow along as Project Aberration comes to life. Our 1956 Dodge truck is being built using the complete driveline, chassis, suspension and other key parts from a 2004 supercharged Viper SRT. This restomod truck will be boosted by plenty of aftermarket power adders and tons of Power & Performance fabrication. Scroll down to see this awesome vehicle in progress.

We began project Aberration using a very clean and unique 1956 Job Rated Dodge pickup that spent its life in California. For the donor vehicle, we used our owner’s fully running and driving 2004 Dodge Viper. The entire Viper, driveline, chassis and suspension have been placed under the truck so it handles and performs just like a Viper. The donor Viper is already loaded with goodies including a supercharger, coil-over suspension, full exhaust and more.

We began the build process by getting the ’56 pickup on the lift so we could tear her down. We wasted no time getting the cab and bed off of the chassis and the interior out of this truck.

With the chassis out of the truck it was time to begin mock-up. Luckily we had a Viper frame section handy to set the cab and bed to measure and check fitment.

We held on as long as we could, but it was finally time to tear off all the body panels from the Viper. She is in go kart form for now, but she will be getting gutted, chopped in half and stretched soon.

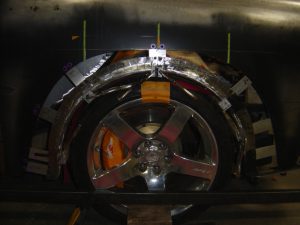

With all of the body panels off of the Viper it was time to gut the interior, get rid of the cowl, windshield frame and test fit under the truck cab.

After the cab was test fit on-top the Viper, we were ready to make some more cuts. We removed the outer rail and floor pan sections on the Viper in preparation for stretching the frame to match the wheelbase of the pickup.

With all the floor pans out, outer rail gone and all measurements taken, it was time to set the Viper up to be cut and stretched. We fabricated some bracing to keep the Viper nice and rigid while we cut and modified the frame.

The time finally came to put the blade to the Viper frame. After all the measurements were taken, and triple checked, it was show time.

After we made the cuts, it was time to stretch the frame and add material in order to achieve the proper wheelbase.

The bed sides were removed from the bed so we could space them out to clear the wider Viper wheels. The cab and bed were set back on top the the Viper so we could get the correct measurements for the rear frame extensions.

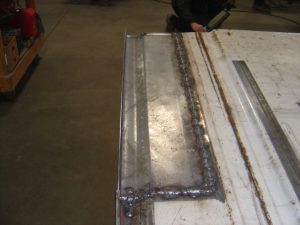

With the wheelbase alterations accomplished, it was time to add structure and rigidity to strengthen the frame under the cab and bed.

Frame fabrication continues on Aberration. When altering a vehicle’s structure so drastically, it is imperative that the frame is made correctly to keep the final product sturdy and safe. The frame not only looks awesome, but it will also provide the rigidity necessary to keep this truck handling like a Viper.

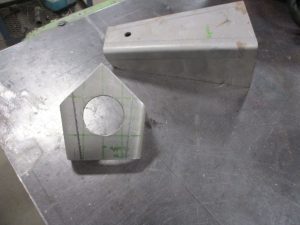

Fabrication work continues as we make new strut towers for Aberration. With the strut towers built it was time to get the body and bed back on to test fit.

With the body back on top of the frame, it was time to figure where everything is going to fit in the cab. Take a look as we fabricate a pedal bracket based on the Viper firewall. Fab and fit continued on the truck as we continued on the firewall and the cab floor.

More fab and fit work as we continue through the rebuild of the firewall and the cab floor.

Interior construction continues with the fabrication of floor pan bracing and foot well construction.

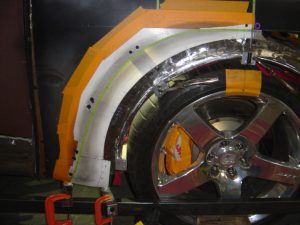

Meanwhile, the party continues in the back with mods to the bed sides as we have to stretch and widen them to clear the Viper wheels and tires.

After the bed sides were squared away, we decided to tackle some areas needing repair, including the passenger front door. Take a look how we properly patched the lower portion of the door.

Now it’s time to move on some to some fun stuff. Take a look at some of the design mockup we are doing in order to get a direction on the body mods that the truck will receive.

Design continues as we mockup a Gen 3 Viper dash, console and seat in the truck.

Fabrication continues on Aberration as we begin creating a cowl and firewall to fit around all of the Viper parts in the cab.

The metal work gets intense as we adjust the wheel openings. Take a look as we tuck, tighten, flare and finish all four corners.

Sign Up

Sign up for our email list to get up-to-date news on projects and rebuilds!

HOURS

Tuesday-Friday

6:30am-5pm ET

Related Posts

Ceramic Coating Explained